A major artificial intelligence and data innovation programme based in Renfrewshire is helping manufacturers across Scotland improve productivity, reduce waste and strengthen their competitiveness.

The £2.2 million Data-Driven Design and Manufacturing Colab (D3M Colab) project is led by the National Manufacturing Institute Scotland (NMIS), which is based at the Advanced Manufacturing Innovation District Scotland (AMIDS) site in Renfrewshire.

So far, the programme has supported 90 organisations and helped upskill more than 250 people, giving engineers and manufacturing teams the practical skills needed to use data science and AI within their own businesses.

Operated by the University of Strathclyde and forming part of the High Value Manufacturing Catapult, NMIS is working with companies to bridge the gap between traditional manufacturing and modern digital technologies.

Through hands-on projects and tailored training delivered from its Renfrewshire base, participating businesses are learning how to apply data-driven methods to real-world challenges, including improving production efficiency, strengthening quality control and improving equipment reliability. Many companies are already embedding these methods directly into day-to-day operations.

Projects with major aerospace and energy firms have focused on automating energy-use analysis and using 3D model-based tolerance tools to cut emissions, reduce material waste and improve the accuracy of critical components.

More than 120 projects have now been delivered across sectors including food and drink, construction and electronics, demonstrating clear improvements in performance, quality and sustainability.

The Renfrewshire-based initiative is also supporting skills development for the future workforce. A project involving West College Scotland and Ailsa Reliability is giving apprentices hands-on experience in condition monitoring, using sensors and digital systems to track machine health and identify early signs of failure.

Andrew Sherlock, Director of Data-Driven Manufacturing at the National Manufacturing Institute Scotland, said the project is helping manufacturers turn digital ambition into practical action.

“Scotland’s manufacturers are ambitious about digital transformation, but many need structured support to move from awareness to real change,” he said. “This project provides businesses with the tools, skills and confidence to embed data-driven approaches that improve efficiency, sustainability and competitiveness.”

Participants receive specialist training in data science for manufacturing, followed by ongoing support from the NMIS AI in Manufacturing team and PhD students from the University of Strathclyde.

The project forms part of the Glasgow City Region Innovation Accelerator programme, funded by Innovate UK on behalf of UK Research and Innovation, which is investing £100 million across 26 research and development projects aimed at accelerating growth in high-potential innovation clusters, including the Glasgow City Region.

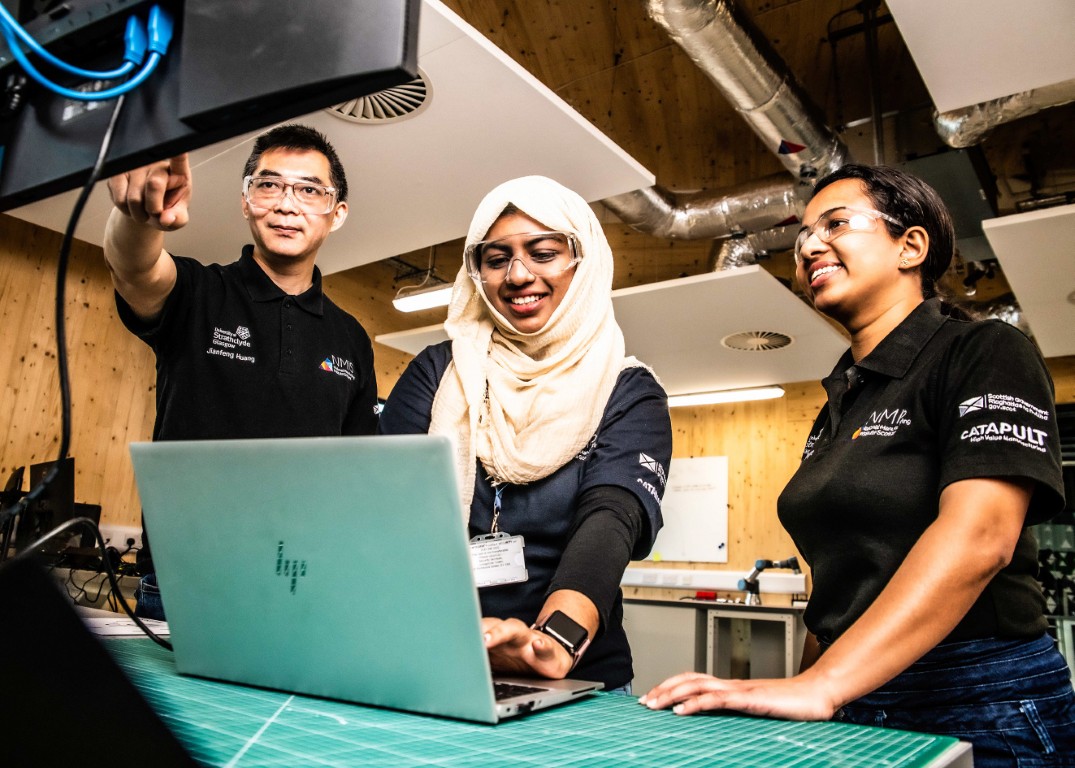

Headline photo: Engineers and researchers work together on a data-driven manufacturing project at the National Manufacturing Institute Scotland’s CoLab facility, based at the Advanced Manufacturing Innovation District Scotland (AMIDS) in Renfrewshire

Photo Credit: National Manufacturing Institute Scotland (NMIS)